Able Hands Orthotics Inc. is an end-to-end service for Patient-Specific Orthoses chauffeuring the industry into the 21st Century.

Orthoses are the treatment of choice for many diagnoses such as fractures, tendonitis, trauma, and crush injuries – these can be applied on the hand, arm, and even lower extremities for protection and facilitate the healing process. Current Orthoses can be off-the-shelf that require adjustments and sizing to be compatible, or hand formed using thermoplastic sheets by skilled therapists. Able Hands Orthotics introduces modern technologies around 3D Scanning and 3D Printing to provide the patient with an orthotic catered specifically to their needs. These orthoses are specifically designed with comfort and healing with in-house algorithms and expertise to ensure they meet rigorous standards that therapists and physicians require.

Generating an Orthosis is as Easy as 1 - 2 - 3!

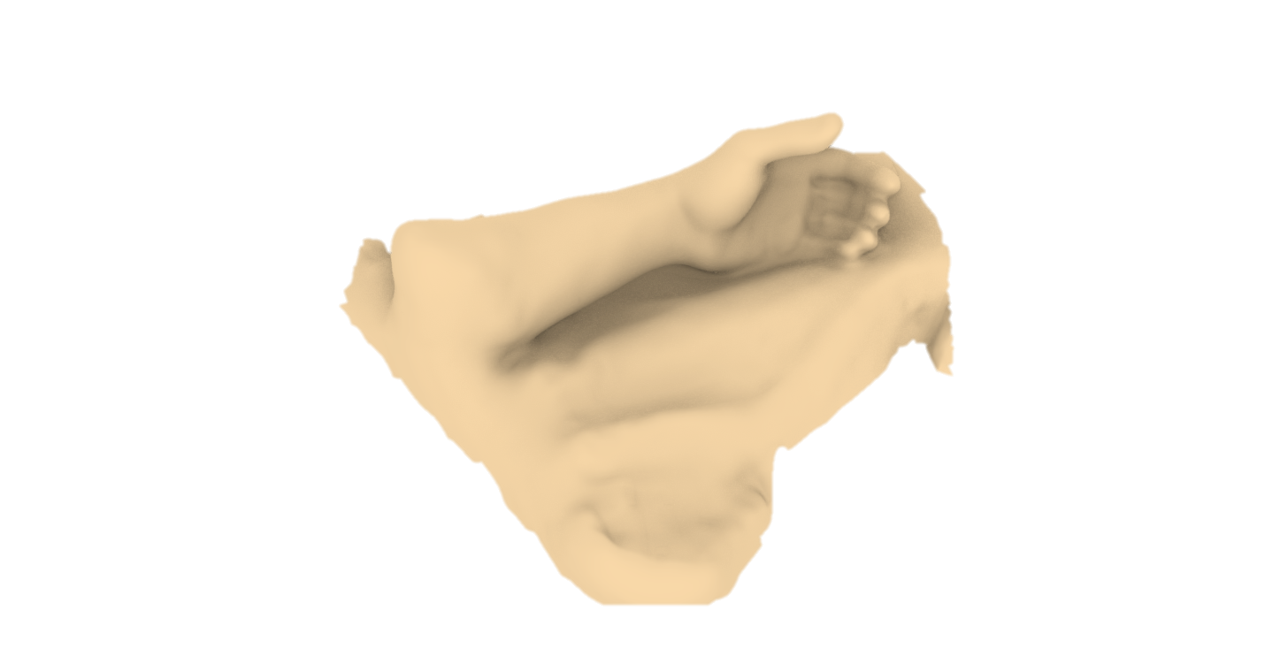

Scan with Able Hands Orthotic Scanner App

Available for iPhones X and Above with no additional accessories. Used to quickly generate a 3D Scan of the Body Part quickly and from the comfort of anywhere around the globe.

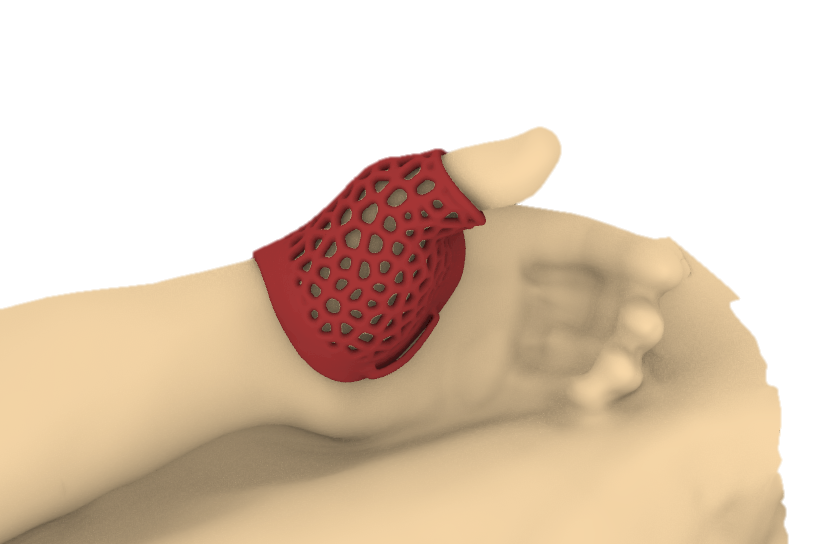

CAD (Computer Aided Design) Algorithm

Our Biomedical Engineer will generate an orthosis according to the diagnosis, prescription, and instructions provided.

Manufacturing via 3D Printing

Using contemporary 3D Printing techniques, the designed Orthosis will be printed in just a few hours.

Orthoses will be shipped with necessary strapping materials to ensure proper immobilization. All patient-facing steps (fitting, adjustments, and guidance) must come from the treating Physician or a practicing Orthotist/Prosthetist.

Please use the form below to get in contact with the team to set up your custom orthosis. Scanner Application is available via invite only.